Industrial Control Servo System

I. Background

Servo system is widely used in industrial automation field as a crucial part of mechatronics products. It performs dynamic control of mechanical equipment position and angle mainly by precisely controlling the speed and direction of the servo motor. With the increasing demand for control algorithms and control accuracy of servo systems in modern industry, FPGA is widely used in the industrial servo field because of its strong functions, high speed, high flexibility and short design cycle.

II. Solution Description

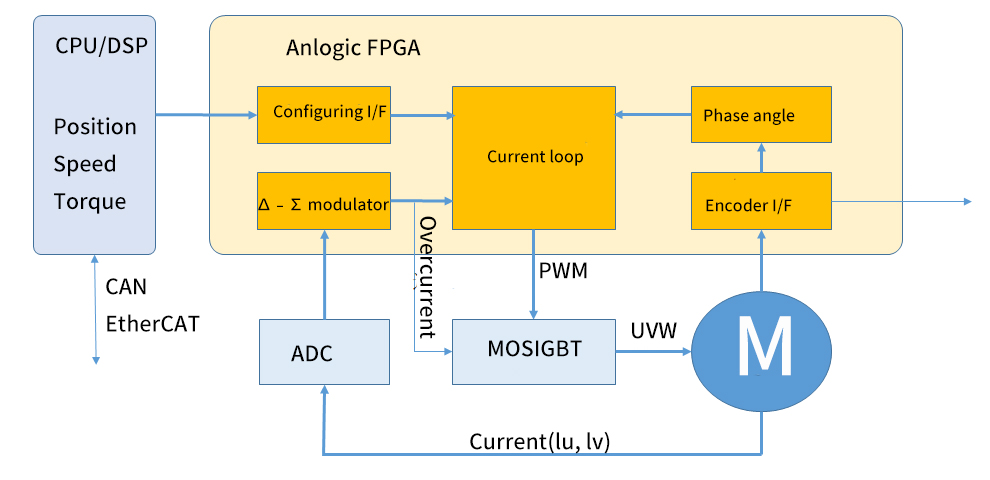

The industrial control servo system based on Anlogic FPGA is shown in the figure. As a co-processor, FPGA mainly offers current loop algorithm, motor driver, encoder, modulator and other functions, and realizes the precise control of the whole servo system with CPU/DSP. It allows customers to select FPGA chips of different capacities according to application requirements, expands multi-axis applications, supports industrial Ethernet, and adapts to more complex systems.

Recommended for Development Kit

Solution Advantages

-

Hardware current loop

FPGA logic offers current loop algorithms with high performance and high accuracy

-

Strong scalability

Rich logic resources to facilitate multi-axis solution development for customers

-

Industrial Ethernet

Support industrial Ethernet, to meet the needs of large-scale and systematization